-

AlexanderFornecedores confiáveis

AlexanderFornecedores confiáveis -

LouisFoi um prazer trabalhar consigo.

LouisFoi um prazer trabalhar consigo.

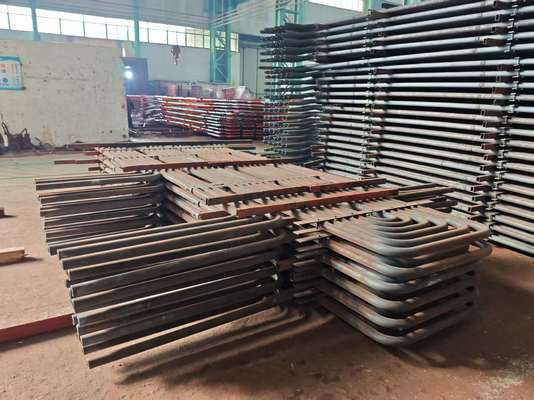

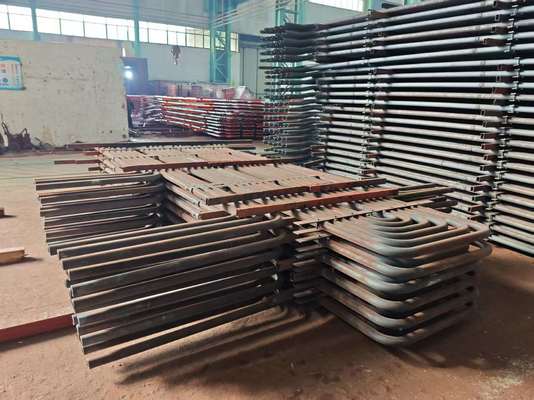

ASME Certified Industrial Power Plant Superheater Coils - High Temp Horizontal Type

| Lugar de origem | China |

|---|---|

| Marca | Saneco |

| Certificação | ASME, EN, GB, ISO |

| Número do modelo | Superaquecedor secundário |

| Quantidade de ordem mínima | 20 toneladas |

| Preço | Negociável |

| Detalhes da embalagem | Estrutura de aço |

| Tempo de entrega | 60 a 80 dias |

| Termos de pagamento | L/C, T/T, Western Union |

| Habilidade da fonte | 6000 toneladas/ano |

Contacte-me para amostras e cupons grátis.

whatsapp:0086 18588475571

WeChat: 0086 18588475571

skype: sales10@aixton.com

Se tiver alguma preocupação, fornecemos ajuda online 24 horas por dia.

x| Tipo de bobina | De forma de U ou recta | Material | Aço carbono, aço ligado, aço inoxidável, cobre, alumínio, etc. |

|---|---|---|---|

| Disposição da bobina | Horizontal ou vertical | Espessura do tubo | Personalizado |

| Cor | Personalizado | Aplicação | Instalação de energia ou incinerador de resíduos |

ASME Certified Industrial Power Plant Superheater Coils - High Temp Horizontal Type

What are the primary risks of superheater coil failure?

Failure may cause high-pressure steam leaks, leading to equipment damage or safety incidents, especially under high-temperature and high-pressure conditions.

Description

A superheater is a component that heats saturated steam in an industrial boiler, turning it into superheated steam. Our superheater guarantees that the superheated steam temperature will fluctuate to within an allowable range (normally varies from 540℃ to 550℃) when the boiler is over loaded.

Superheaters and reheaters are important parts for the heating surfaces, used to increase steam temperature, aiming to improve steam enthalpy and further to increase the thermal circulation efficiency for power station.

The superheater, reheater and economizer of the boiler adopt serpentine tube heating surface. Due to a series of characteristics such as large number, different bending radius and many welded joints, the manufacturing process of serpentine heating surface is more complex and the productivity is lower. In recent years, in order to change this backward production appearance, China's major boiler plants have taken a series of measures in design and technology to improve the universality of product parts and components, creating necessary conditions for the mechanization, automation and organization of automatic production lines of serpentine pipe production. At present, China's major boiler plants have adopted automatic production lines with program control for the manufacture of coil heating surfaces.

![]()

Differences

| Type | Advantages | Disadvantages | Supporting method |

| Pendant-type | 1.Firm structural support | 1. Flow blockage by condensed steam 2. Needs slow restart to purge the water that accumulates in the bottom. | supported from above |

| Inverted-type | 1.Proper drainage of the condensed steam | 1. Lack the structural rigidity, especially in high speed gas flow | Supported from below |

| Horizontal -type |

1. Proper drainage 2. Good structural rigidity. |

1. They do not view the flam directly so they are mainly from the convective type | Usually supported in the vertical gas ducts parallel to the main furnace. |