-

AlexanderFornecedores confiáveis

AlexanderFornecedores confiáveis -

LouisFoi um prazer trabalhar consigo.

LouisFoi um prazer trabalhar consigo.

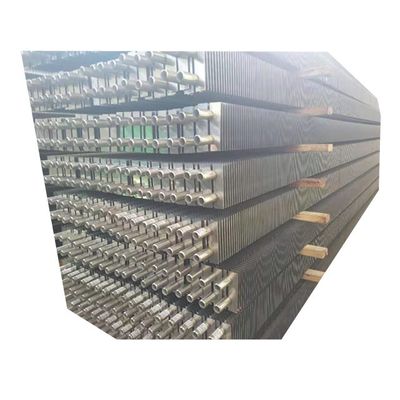

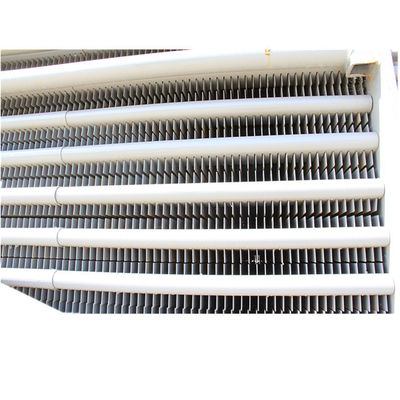

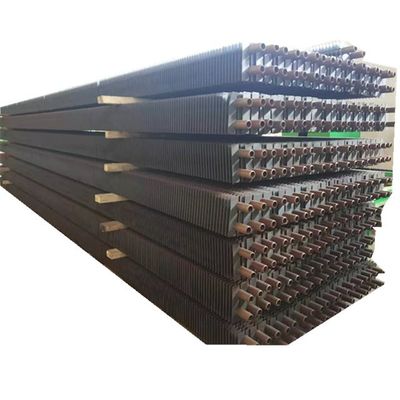

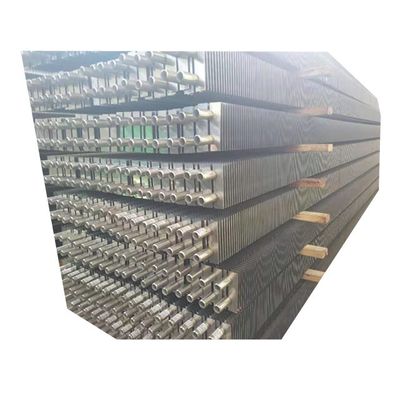

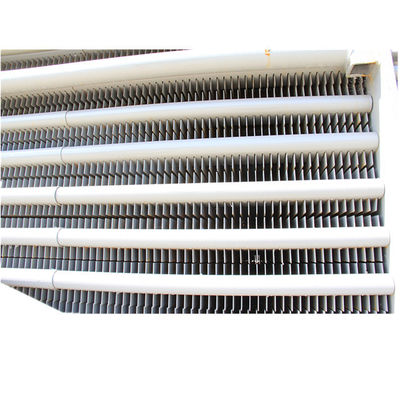

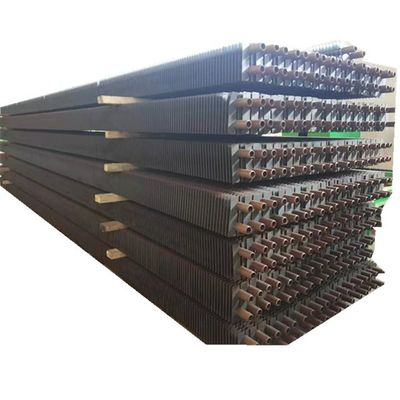

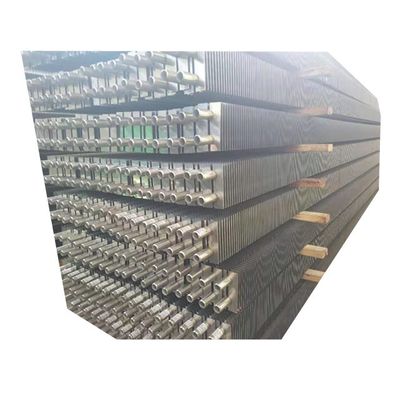

Economizador de Tubos com Aletas H com Produção Máxima de Vapor de 20t/h, Garantia de 1 Ano e Garantia de 5 Anos para Componentes Principais

Contacte-me para amostras e cupons grátis.

whatsapp:0086 18588475571

WeChat: 0086 18588475571

skype: sales10@aixton.com

Se tiver alguma preocupação, fornecemos ajuda online 24 horas por dia.

x| Tipo | Circulação natural | Estrutura | Tubos de incêndio e de água |

|---|---|---|---|

| Pressão | Baixo/de alta pressão | Produção de vapor | Max. 20 t/h |

| Estilo | Vertical | Combustível | Carvão / Gás / Combustível a carvão / aquecimento por água |

| Saída | Água quente/vapor | Tratamento de superfície | Pintado |

| Material | Aço de liga, aço carbono, SA210C, SA213T22 | Padrão de material | ASTM, EN ou ISO |

| Faixa de peso | 10 toneladas - 1000 toneladas | Processo de fusão | EF+LF + VD |

| Processo | Material-> Ingot-> Hot/Cold-Rolling-> Tratamento térmico-> Inspeção-> Maixa Avada | Padrão de UT | ASTM A388 ou EN10228 |

| Tipo de trocador de calor | Economizador de tubo com acabamento em H. | ||

| Destacar | Economizador de Tubos com Aletas H com Produção Máxima de Vapor de 20t/h,Garantia de 1 Ano para Economizador de Tubos com Aletas H,Garantia de 5 Anos para Componentes Principais do Economizador de Tubos com Aletas H |

||

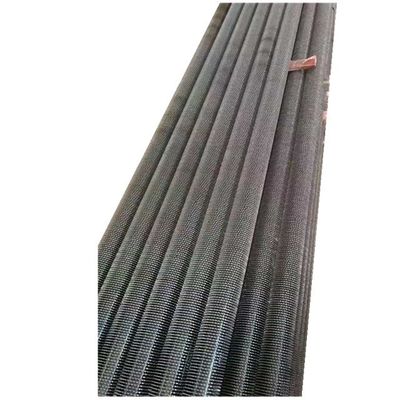

Os economizadores de caldeira são dispositivos de troca de calor de alta eficiência com tubos aletados projetados para aquecer líquidos (tipicamente água) sem atingir o ponto de ebulição. Fabricamos três tipos de economizadores de caldeira:

- Economizador de tubo liso

- Economizador de tubo com aleta H

- Economizador de tubo com aleta espiral

- Aumenta a área de troca de calor, reduzindo o número de tubos necessários

- Aumenta a área de fluxo de gás de combustão para reduzir a velocidade do fluxo e a abrasão

- Disponível na configuração de tubo com aleta H dupla para maior rigidez em fileiras de tubos longos

- Superior aos projetos de tubos lisos em eficiência e durabilidade

O economizador reduz significativamente os custos de resfriamento, otimizando a eficiência da transferência de calor, permitindo o desligamento do compressor, mantendo a capacidade de resfriamento adequada.

| Descrição | Economizador de caldeira |

|---|---|

| Material | Aço liga, Aço carbono, SA210C, SA213T22 |

| Padrão do material | ASTM, EN ou ISO |

| Dimensão | Personalizável |

| Peso | 10-1000 toneladas |

| Processo de Fusão | EF+LF+VD |

| Processo de Fabricação | Material→Lingote→Laminação a quente/frio→Tratamento térmico→Inspeção→Usinagem grosseira→UT→2º Tratamento térmico→Usinagem de acabamento→Inspeção final |

| Padrão UT | ASTM A388 ou EN10228 |

- Relatórios de cálculo de resistência e teste de impacto com informações sobre o material

- 100% NDT (testes não destrutivos) de placa de aço, tubo e eletrodo

- Inspeção por raio-X, raio-γ e teste de penetrante líquido para todas as soldas

- Relatórios de teste hidráulico para verificar a pressão de trabalho e os padrões de segurança