-

AlexanderFornecedores confiáveis

AlexanderFornecedores confiáveis -

LouisFoi um prazer trabalhar consigo.

LouisFoi um prazer trabalhar consigo.

Economizador de Caldeira de Alta Eficiência com Produção Máxima de Vapor de 20t/h e 5 Anos de Garantia para Componentes Principais

Contacte-me para amostras e cupons grátis.

whatsapp:0086 18588475571

WeChat: 0086 18588475571

skype: sales10@aixton.com

Se tiver alguma preocupação, fornecemos ajuda online 24 horas por dia.

x| Tipo | Circulação natural | Estrutura | Tubos de incêndio e de água |

|---|---|---|---|

| Pressão | Baixo/de alta pressão | Produção de vapor | Max. 20 t/h |

| Estilo | Vertical | Combustível | Carvão / Gás / Combustível a carvão / aquecimento por água |

| Saída | Água quente/vapor | Material | Aço de liga, aço carbono, SA210C, SA213T22 |

| Padrão de material | ASTM, EN ou ISO | Faixa de peso | 10 toneladas - 1000 toneladas |

| Processo de fusão | EF+LF+VD | Processo | Material-> Ingot-> Hot/Cold-Rolling-> Tratamento térmico-> Inspeção-> Maixa Avada |

| Padrão de UT | ASTM A388 ou EN10228 | Tratamento de superfície | Pintado |

| Dimensão | personalizado | ||

| Destacar | Economizador de Caldeira com Produção Máxima de Vapor de 20t/h,Economizador de Caldeira com 1 Ano de Garantia,Economizador de Caldeira com 5 Anos de Garantia para Componentes Principais |

||

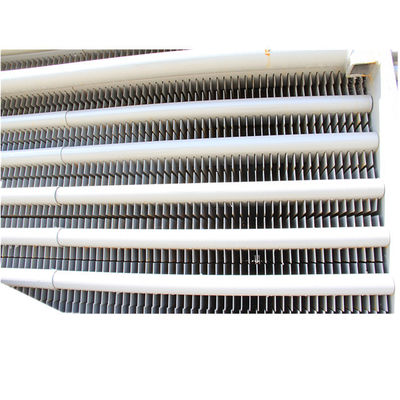

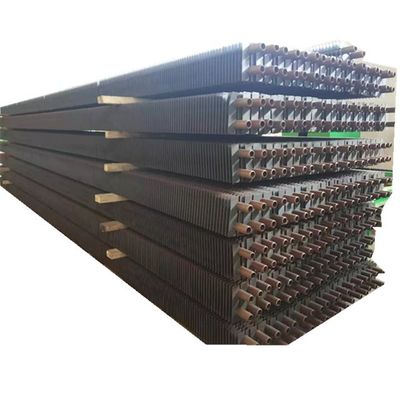

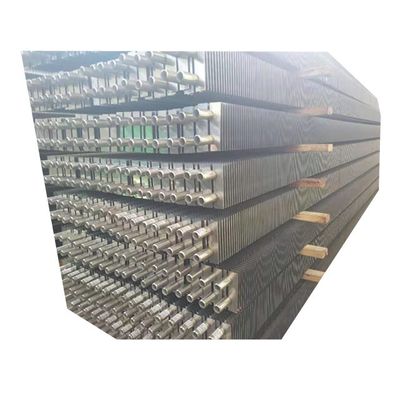

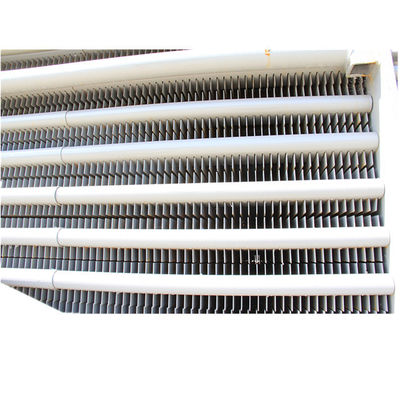

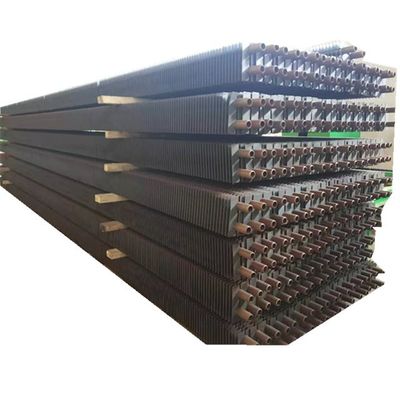

Os economizadores de caldeira são dispositivos de troca de calor com tubos com nadadeiras que aquecem líquidos (normalmente água) sem exceder o ponto de ebulição do líquido.

- Economisador de tubos nus

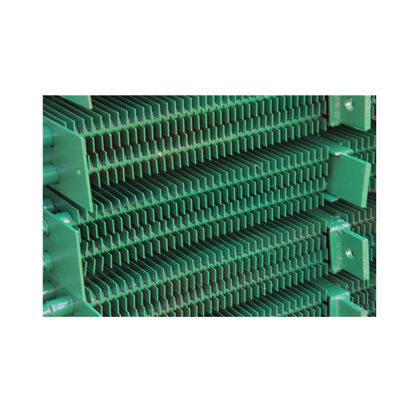

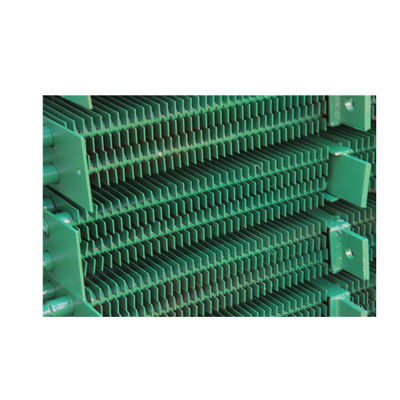

- Economizador de tubos com nadadeira H

- Máquinas e aparelhos de limpeza

O economizador de tubos com barbatanas H é um trocador de calor altamente eficiente composto por tubos com barbatanas H. Em comparação com os economizadores de tubos nus, os modelos com barbatanas H oferecem:

- Área de troca de calor alargada

- Número reduzido de tubos necessários

- Área de fluxo de gases de combustão aumentada

- Redução da velocidade de fluxo dos gases de combustão e da abrasão

Os tubos com nadadeira H podem ser fabricados como tubos com nadadeira H dupla para aumentar a rigidez em fileiras longas de tubos.O economizador de barbatanas em espiral apresenta um novo design com tubos de barbatanas em espiral para superar problemas de abrasão e prolongar a vida útil.

A principal função do economizador é reduzir os custos de arrefecimento, permitindo a desligação do compressor, mantendo a capacidade de arrefecimento adequada, resultando em uma economia de energia significativa.

| Descrição | Economizador de caldeiras |

|---|---|

| Materiais | Aço ligado, aço carbono, SA210C, SA213T22, etc. |

| Norma de materiais | ASTM, EN ou ISO, etc. |

| Dimensão | Personalização |

| Peso | Min: 10 toneladas Max.: 1000 toneladas |

| Processo de fusão | EF+LF + VD |

| Processo | Material-> Ingot -> Rolamento a quente/a frio-> Tratamento térmico (normalização + temperamento) -> Inspecção -> Mecânica bruta-> UT -> 2o Tratamento térmico -> Mecânica de acabamento -> Inspecção |

| Padrão UT | ASTM A388 ou EN10228, etc. |

Zhangjiagang Hua Dong Boiler Co., Ltd., fundada em 1985, especializada na fabricação de caldeiras de centrais elétricas, caldeiras industriais, caldeiras de incineração de resíduos,Caldeiras de biomassa e componentes de superfície de aquecimento relacionadosFornecemos serviços abrangentes desde a concepção e fabricação até à instalação e manutenção.

38 anos de experiência em investigação, desenvolvimento e fabrico industriais com capacidade de produção suficiente.

- Relatório do ensaio de impacto e do cálculo da resistência com informações sobre os materiais aplicados

- Relatório 100% NDT (inspecção não destrutiva) de chapas, tubos e eletrodos de aço

- Relatório de inspecção de raios-X, raios-γ e penetração de líquidos (costura de solda)

- Relatório de ensaio hidráulico para assegurar a pressão de trabalho e a segurança normais

O nosso sistema de garantia da qualidade cumpre com as regulamentações e normas nacionais,assegurar um controlo 100% dos processos e produtos através de inspecções rigorosas dos materiais e dos produtos durante a produção.

Para cargas especiais (excesso de comprimento, largura, altura e peso), usamos caixas de armação para facilitar o manuseio.

Para mercadorias normais, preferimos contentores normais.

Todas as mercadorias são reforçadas após o carregamento para um transporte seguro.

ISO 9001:2015; certificado CE; EN ISO 3834-2; certificado ASME com carimbos "S", "U" e "NB", etc.

Oferecemos garantia de 18 meses para todas as peças sobressalentes (excluindo peças frágeis).

- Todas as máquinas cumprem os requisitos do sistema ISO de qualidade e CE

- Cada procedimento é executado por mão de obra profissional qualificada com QC dedicado

- Todas as informações do produto são rastreadas em nosso sistema de gestão eficiente

Caldeira CFB, Caldeira HRSG, Economizador de Caldeira, Tubos de Boiler Fin, Pré-aquecedor de Ar da Caldeira, Superaquecedor da Caldeira, Parede da membrana da Caldeira, cabeçotes dos colectores da Caldeira e outras peças sob pressão.

Antes das vendas:

Informação sobre produtos, previsão de pesquisas de mercado, personalização de produtos, processamento de produtos, consultoria e outros serviços.

Após-venda:

- Formação técnica de acordo com as exigências do cliente

- Substituições de garantia

- Fornecimento de peças sobressalentes de manutenção

- Acompanhamento regular dos clientes

- Resposta rápida às reclamações e consultas

Termos de entrega:FOB, CFR, CIF, EXW, FCA

Moeda de pagamento:USD, CNY

Tipo de pagamento:T/T, L/C, MoneyGram, Western Union, em dinheiro

Língua falada:Inglês, chinês

Somos uma fábrica localizada a 130km (2 horas de carro) do aeroporto de Xangai. Oferecemos serviço de recolha em Xangai para sua visita.