Todos os Produtos

-

AlexanderFornecedores confiáveis

AlexanderFornecedores confiáveis -

LouisFoi um prazer trabalhar consigo.

LouisFoi um prazer trabalhar consigo.

Economizador de Caldeira de Alta Eficiência com Produção Máxima de Vapor de 20t/h e 5 Anos de Garantia para Uso Industrial

Contacte-me para amostras e cupons grátis.

whatsapp:0086 18588475571

WeChat: 0086 18588475571

skype: sales10@aixton.com

Se tiver alguma preocupação, fornecemos ajuda online 24 horas por dia.

xDetalhes do produto

| Tipo | Circulação natural | Estrutura | Tubos de incêndio e de água |

|---|---|---|---|

| Pressão | Baixo/de alta pressão | Produção de vapor | Max. 20 t/h |

| Estilo | Vertical | Combustível | Carvão / Gás / Combustível a carvão / aquecimento por água |

| Saída | Água quente/vapor | Tratamento de superfície | Pintado |

| Material | Aço de liga, aço carbono, SA210C, SA213T22 | Padrão de material | ASTM, EN ou ISO |

| Faixa de peso | 10 toneladas a 1000 toneladas | Processo de fusão | EF+LF + VD |

| Processo | Material-> Ingot-> Hot/Cold-Rolling-> Tratamento térmico-> Inspeção-> Maixa Avada | Padrão de UT | ASTM A388 ou EN10228 |

| Tratamento térmico | Normalizando+ temperamento | ||

| Destacar | Economizador de Caldeira com Produção Máxima de Vapor de 20t/h,Economizador de Caldeira com 5 Anos de Garantia,Economizador de Caldeira para Uso Industrial |

||

Descrição de produto

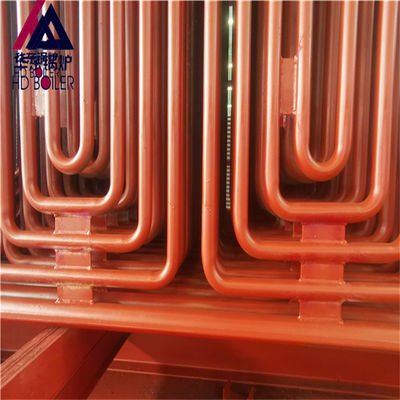

Peças de reposição para economizador de caldeira, equipamento de caldeira de gás de exaustão, caldeira a vapor

Descrição do Produto

Os economizadores de caldeira são dispositivos de troca de calor com tubos aletados que aquecem líquidos (normalmente água) sem exceder o ponto de ebulição do líquido. Fabricamos três tipos de economizadores de caldeira:

- Economizador de tubo liso

- Economizador de tubo aletado em H

- Economizador de tubo aletado em espiral

O economizador de tubo aletado em H é um trocador de calor altamente eficiente, composto por tubos aletados em H. Comparado aos economizadores de tubo liso, ele oferece:

- Maior área de troca de calor com menos tubos

- Aumento da área de fluxo de gás de combustão para reduzir a velocidade do fluxo e a abrasão

- Disponível como tubos duplos aletados em H para maior rigidez em fileiras de tubos longos

O economizador aletado em espiral apresenta equipamentos de transferência de calor recém-projetados com tubos aletados em espiral para superar a abrasão severa e prolongar a vida útil.

Função

O economizador reduz os custos de resfriamento, permitindo o desligamento do compressor, mantendo a capacidade de resfriamento adequada, resultando em economia significativa de energia.

Especificações

| Descrição | Economizador de caldeira |

|---|---|

| Material | Aço liga, aço carbono, SA210C, SA213T22, etc. |

| Padrão do material | ASTM, EN ou ISO etc. |

| Dimensão | Personalização |

| Peso | Mín: 10 toneladas Máx.: 1000 toneladas |

| Processo de fundição | EF+LF + VD |

| Processo | Material→Lingote → Laminação a quente/frio→ Tratamento térmico (Normalização+ têmpera) → Inspeção →usinagem grosseira→UT →2º Tratamento térmico →usinagem de acabamento →Inspeção |

| Padrão UT | ASTM A388 ou EN10228, etc |

Controle de Qualidade

- Relatório de cálculo de teste de impacto e resistência com informações sobre os materiais aplicados

- Relatório de inspeção 100% NDT (inspeção não destrutiva) de chapa de aço, tubo e eletrodo

- Relatório de inspeção de raio-X, γ-raios e teste de penetrante líquido (costura de solda)

- Relatório de teste hidráulico para garantir a pressão de trabalho padrão e segurança

Produtos Similares

Informações da Empresa

Certificado

Embalagem e Envio

Perguntas frequentes

Entre em contato conosco

Produtos recomendados