-

AlexanderFornecedores confiáveis

AlexanderFornecedores confiáveis -

LouisFoi um prazer trabalhar consigo.

LouisFoi um prazer trabalhar consigo.

Economizador de caldeira horizontal de alta eficiência térmica com garantia de 1 ano e design de tubo serpentino

Contacte-me para amostras e cupons grátis.

whatsapp:0086 18588475571

WeChat: 0086 18588475571

skype: sales10@aixton.com

Se tiver alguma preocupação, fornecemos ajuda online 24 horas por dia.

x| Tipo | Circulação natural | Estrutura | tubo de água |

|---|---|---|---|

| Pressão | Alta pressão | Produção de vapor | Max. 60 t/h |

| Estilo | horizontal | Combustível | Aquecidos a carvão |

| Saída | Água quente | Material | Placas de aço de caldeiras especiais |

| Eficiência térmica | 92,4%--94,5% | Pressão de trabalho | Alta pressão |

| Peso | 1-20 toneladas | Processo de fusão | EF+LF + VD |

| Padrão de material | ASTM, EN ou ISO etc. | Padrão de UT | ASTM A388 ou EN10228, etc |

| Processo | Material-> Ingot -> Hot/Cold -Rolling-> Tratamento térmico (normalização+ temering) -> I | ||

| Destacar | Economizador de caldeiras de alta eficiência térmica,Economizador de caldeira horizontal,Garantia de 1 ano Economizador de tubos de serpentina |

||

Os economizadores de caldeira são dispositivos de troca de calor com tubos aletados que aquecem líquidos (tipicamente água) a temperaturas abaixo de seu ponto de ebulição. Fabricamos três tipos de economizadores de caldeira:

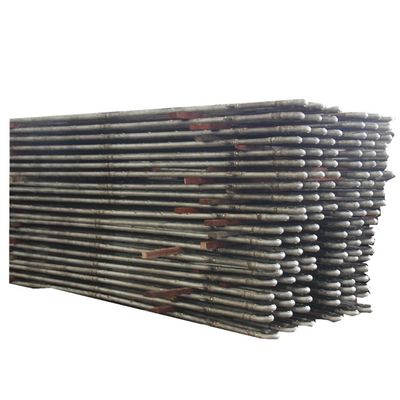

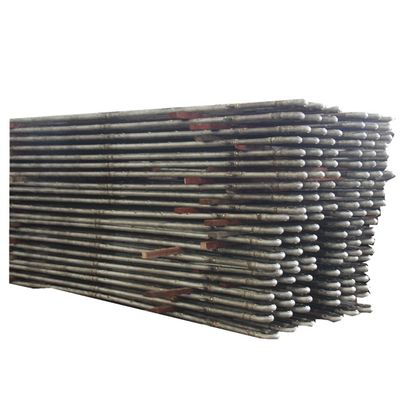

- Economizador de tubo liso

- Economizador de tubo com aletas em H

- Economizador de tubo com aletas espirais

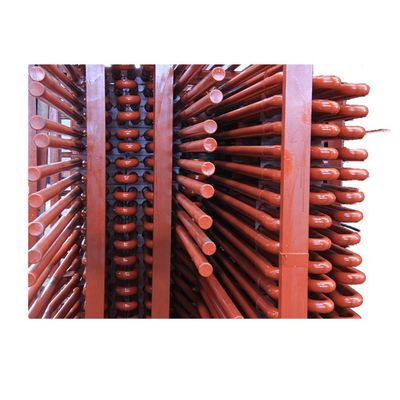

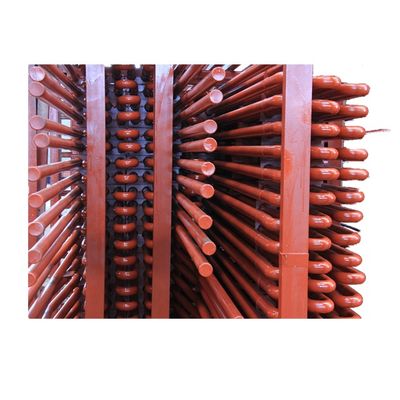

O economizador de tubo com aletas em H é um trocador de calor de alta eficiência composto por tubos com aletas em H. Comparado aos economizadores de tubo liso, ele oferece:

- Área de troca de calor aumentada

- Número reduzido de tubos necessários

- Área de fluxo de gás de combustão expandida para diminuir a velocidade do fluxo e a abrasão

Os tubos com aletas em H podem ser fabricados como tubos com aletas em H duplos para maior rigidez, tornando-os adequados para fileiras de tubos longos.

O economizador com aletas espirais apresenta um novo design com tubos com aletas espirais que abordam sérios problemas de abrasão e prolongam a vida útil.

| Descrição | Economizador de caldeira |

|---|---|

| Material | Aço liga, aço carbono, SA210C, SA213T22, etc. |

| Padrão do material | ASTM, EN ou ISO etc. |

| Dimensão | Personalização |

| Peso | Mín: 10 toneladas Máx: 1000 toneladas |

| Processo de fundição | EF+LF + VD |

| Processo | Material→Lingote→Laminação a quente/frio→Tratamento térmico (Normalização+ têmpera)→Inspeção→Usinagem grosseira→UT→2º Tratamento térmico→Usinagem de acabamento→Inspeção |

| Padrão UT | ASTM A388 ou EN10228, etc |

- Relatório de cálculo de teste de impacto e resistência com informações sobre os materiais aplicados

- Relatório de 100% NDT (inspeção não destrutiva) de chapa de aço, tubo e eletrodo

- Relatório de inspeção de teste de raio-X, raio-γ e penetrante líquido (costura de solda) para garantir a qualidade da caldeira

- Relatório de teste hidráulico para verificar a pressão de trabalho padrão e a segurança