Todos os Produtos

-

AlexanderFornecedores confiáveis

AlexanderFornecedores confiáveis -

LouisFoi um prazer trabalhar consigo.

LouisFoi um prazer trabalhar consigo.

Economizador de caldeira de baixa e alta pressão com produção de vapor e circulação natural de 60 t/h no máximo

Contacte-me para amostras e cupons grátis.

whatsapp:0086 18588475571

WeChat: 0086 18588475571

skype: sales10@aixton.com

Se tiver alguma preocupação, fornecemos ajuda online 24 horas por dia.

xDetalhes do produto

| Tipo | Circulação natural | Estrutura | Tubos de incêndio e de água |

|---|---|---|---|

| Pressão | Baixo/de alta pressão | Produção de vapor | Max. 60 t/h |

| Estilo | Vertical | Combustível | Aquecidos a carvão |

| Saída | Água quente/vapor | Tratamento de superfície | Pintado |

| Tubo nua od | 25-1650 mm | Espessura do tubo nu | 2-40 mm |

| Espessura da barbatana | 00,6-3,0 mm | Altura da barbatana | 5-30 mm |

| Caminho do tubo de barbatana | 5-30 mm | Comprimento do tubo de barbatana | ≤12000 mm |

| Material | Aço carbono, liga, aço austenítico | ||

| Destacar | Economisador de caldeira de produção de vapor de 60 t/h,Economizador de caldeira de baixa e alta pressão,Economizador de caldeira de circulação natural |

||

Descrição de produto

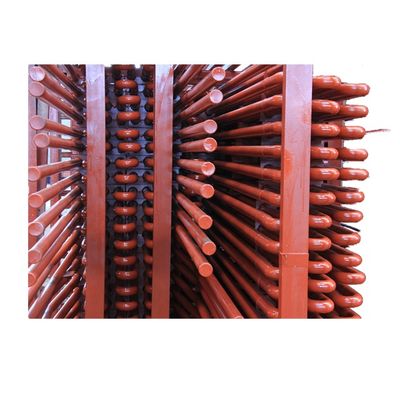

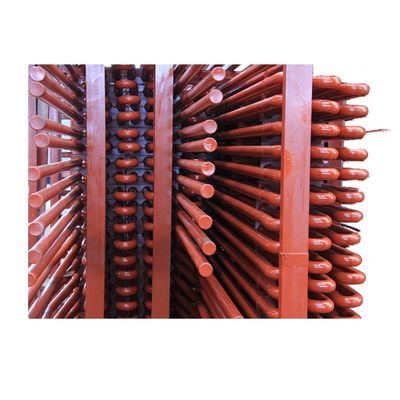

Caldeira de gases de combustão de baixa / alta pressão Economizador Dispositivos de trocador de calor com tubos finados

Economizador de caldeira

Introdução

Os economizadores desempenham uma função fundamental na obtenção de uma elevada eficiência térmica global da caldeira, recuperando a energia de baixo nível dos gases de combustão antes da sua expulsão para a atmosfera.Eles recuperam essa energia aquecendo a água de alimentação da caldeiraOs economizadores são superfícies tubulares de transferência de calor utilizadas para pré-aquecer a água de alimentação da caldeira antes de entrar no tambor de vapor ou nas superfícies do forno.Redução dos custos operacionais através da recuperação de energia extra dos gases de combustão.

Procedimento

Os economizadores reduzem o potencial de choque térmico e fortes flutuações da temperatura da água à medida que a água de alimentação entra no tambor ou nas paredes de água.Também ajudam a cumprir regulamentos ambientais rigorosos que limitam as emissões de óxidos de azoto e dióxido de enxofreO coeficiente de transferência de calor do lado do gás é muito inferior ao coeficiente do lado da água, pelo que as superfícies externas dos tubos podem ser revestidas com nadadeiras para aumentar a área de transferência de calor.O projecto do economizador visa a obtenção da transferência de calor necessária a um custo mínimo, sendo o critério-chave a velocidade máxima admissível dos gases de combustão.

Especificações

| Nome (unidade) | Especificação (mm) |

|---|---|

| Tubos nus (OD) | 25-1650 |

| Tubos nus (espessura) | 2 a 40 |

| Fin (espessura) | 0.6-3.0 |

| Fin (Alta) | 5 a 30 |

| Percurso do fio do tubo de barbatanas | 5 a 30 |

| comprimento do tubo de barbatana | ≤ 12000 |

Materiais:Aço carbono, liga, aço austenítico (níquel e cromo ou manganês)

Controle de qualidade

- Relatório do ensaio de impacto e do cálculo da resistência com informações sobre os materiais aplicados

- Relatório 100% NDT (inspecção não destrutiva) de chapas, tubos e eletrodos de aço

- Relatório de inspecção de raios-X, raios-γ e penetração de líquidos (costura de solda) para assegurar a qualidade da caldeira

- Relatório de ensaio hidráulico para assegurar a pressão de trabalho e a segurança normais

Produtos similares

Informações sobre a empresa

Certificado

Embalagem e transporte

Perguntas frequentes

Contacte-nos

Produtos recomendados